Introduction:

TIG (Tungsten Inert Gas) welding is a widely used welding procedure for sheet metal. This article explores the benefits of TIG welding, its applications, and the process involved in welding thin sheets.

TIG Welding: The Ideal Choice for Thin Sheet Metal:

TIG sheet metal welding is a precise arc welding method that utilizes a tungsten electrode and an inert gas, such as argon or helium, to protect the electrode. It is commonly used in both continuous and spot welding applications, especially in the aviation sector.

Applications in Various Industries:

Originally developed during World War II to replace rivets with welds in aircraft, TIG welding has found extensive use in the industrial sector. Its ability to produce high-quality joints makes it ideal for welding thin sheets.

High-Quality Joints for Thin Sheets:

Compared to traditional welding methods, TIG welding minimizes the risk of piercing the metal, resulting in high-quality joints. The process ensures precision and control while avoiding excessive heat input.

The Process of TIG Welding for Sheet Metal:

In TIG welding, a tungsten electrode is inserted into the torch, surrounded by a protective inert gas. The operator moves the torch along the joint, melting the edges of the metal with the electrode while adding filler material if necessary.

Material Supply and Welding Technique:

TIG welding allows for manual or mechanical material supply, depending on the specific requirements. It is particularly effective in welding thin stainless steel, where the edges are melted, and small amounts of filler material are added for reinforcement.

Proper Torch Handling and Electrode Placement:

Maintaining the correct distance between the tungsten electrode and the joint is crucial to ensure successful TIG welding. The operator must avoid direct contact between the electrode and the metal to prevent sticking and disruption of the welding process.

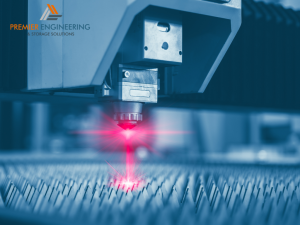

Premier Engineering & Storage Solutions: Your Sheet Metal Expert:

At Premier Engineering & Storage Solutions, we specialize in cutting-edge sheet metal manufacturing services. Our expertise extends to laser cutting, CNC cutting, and CNC punching. Additionally, we offer industrial shelving units, metal storage cabinets, and other storage solutions.

Conclusion:

TIG welding is a versatile and reliable method for welding thin sheet metal. Its ability to produce high-quality joints, combined with its widespread applications, makes it a preferred choice in various industries. Premier Engineering & Storage Solutions provides comprehensive sheet metal manufacturing services and storage solutions to meet your specific needs. Choose TIG welding for precision, durability, and excellence in sheet metal fabrication.