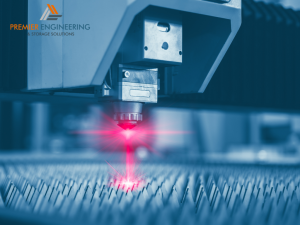

Industrial shelving is an essential component of modern storage solutions. With laser cutting technology, clean and precise cuts can be achieved on various sheet metal materials. This article explores the advantages of sheet metal laser cutting and highlights the benefits it offers for efficient storage solutions.

High Precision Cuts:

Achieve clean and precise cuts on sheet metal of any shape or size using laser cutting technology. The resulting cut edges are exceptionally clean and accurate, ensuring superior quality and craftsmanship.

Minimal Maintenance Requirements:

Industrial shelving equipped with laser cutting machines requires minimal maintenance due to the longevity of the equipment. This results in significant cost savings and allows for uninterrupted operations.

Versatility in Material Options:

Sheet metal laser cutting is compatible with a wide range of metallic materials, including iron, stainless steel, aluminum, and copper. This versatility allows for greater flexibility in material selection based on specific project requirements.

Combustion and Fusion Cutting Processes:

Sheet metal laser cutting utilizes two primary cutting processes. Combustion cutting employs oxygen, while fusion cutting uses inert gas to remove melted metal debris. Both methods provide effective and efficient results, depending on the desired outcome.

State-of-the-Art Sheet Metal Manufacturing Services:

At Premier Engineering & Storage Solutions, we specialize in state-of-the-art sheet metal manufacturing, offering laser cutting services, CNC cutting services, and CNC punching services. Our expertise lies in providing tailored solutions for sheet metal projects, ensuring high-quality results.

Optimize Storage with Industrial Shelving Units:

In addition to sheet metal services, we offer a wide range of industrial shelving units, including metal storage cabinets and shelving units. Our storage solutions are designed to maximize efficiency, organization, and accessibility, providing a streamlined approach to storage management.

Conclusion:

Industrial shelving, combined with sheet metal laser cutting technology, revolutionizes storage solutions by offering high precision, minimal maintenance requirements, and versatility in material options. Premier Engineering & Storage Solutions specializes in delivering cutting-edge sheet metal manufacturing services and storage solutions that meet the diverse needs of various industries.

Upgrade your storage systems and experience the benefits of industrial shelving and sheet metal laser cutting today.